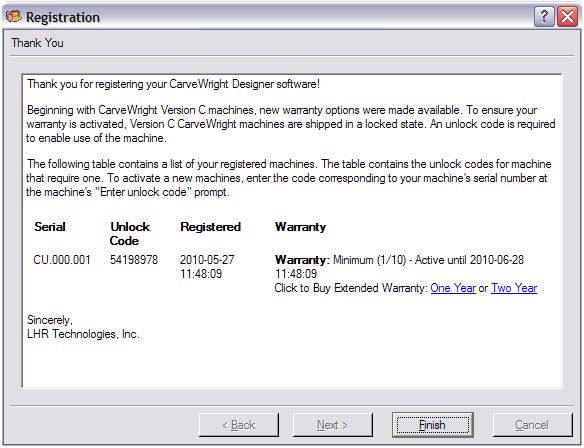

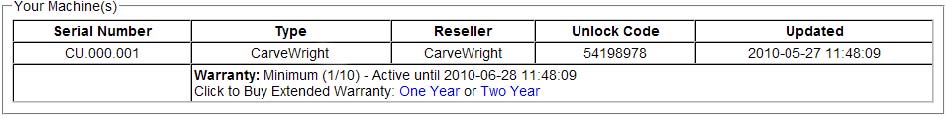

All newer CarveWright machines, starting with Serial Numbers beginning with the letter C, will have to be registered and unlocked prior to use. To view the detailed instructions on how to register your new C-Series Machine, visit the CarveWright website under the “Learn” tab or consult the Software Manual found in the CarveWright Designer Software (Under the “Help” tab) or on the CD included with your machine. At the conclusion of the online machine registration, the user will be presented with an unlock code. C-Series Machines will require this unlock code be entered into the keypad at the machine before proceeding with any operations. The unlock code is eight numbers long and will be shown on the “Thank You” page at the end of the software registration process.

If you do not record the unlock code during registration it can be found by logging in to your Customer Account webpage at register.carvewright.com.

When turning on your CarveWright CX Machine for the first time, the LCD screen will display a prompt indicating that registration is required. Press any key to advance to the Unlock Code screen. Enter the Unlock Code you obtained above and press the “ENTER” button. The display will advance if the code is correct and will remain unchanged for an incorrect code.

If the machine’s LCD shows only “CarveWright Woodworking Machine”, then the firmware version on the memory card needs to be updated to at least version 1.170. Use the Software Manual in the Designer Software (found in “Help” tab) or on the supplied CD for instructions on how to update the firmware.