DOWNLOADABLE PDF INSTRUCTIONS

User Calibration Instructions (PDF)

Calibrating the Machine Offsets

The “Calibrate Offsets” function allows the user to fine tune the machine’s calibration settings for best tracking and measuring performance. There are three calibration settings that can be changed by the user: the X axis (in and out direction), the Y axis (side-to-side direction) and the board thickness settings can all be adjusted.Calibrating the X-AxisThe most frequently calibrated setting is the X-axis. You will want to consider calibrating the X-axis if you are consistently getting an incorrect board length measurement or if you are replacing the factory sandpaper belts with the rubber belts.

To do this calibration you will need a board roughly 36″ long that is clean and straight. It is very important that the board edge that is placed into the machine up against the squaring plate be very clean and free of defects. This is the edge that the board tracking sensor roller will be running on and measuring.

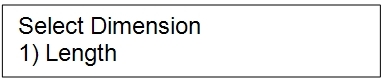

Measure and record your board length with as much accuracy as you can get. Make sure to perform the measurement in the center of the board width, as this is where the machine will also measure (Hand Measured Length – _______inches). Load the board into your machine and measure it using the “Measure Board” function. This can be accessed by pressing the “7” (Measure) key on the keypad or by using the up/down arrows to navigate to the measure function from the CarveWright Main Menu. The display will then ask for the direction the user wishes to measure.

Press the “1” key on the keypad to measure the Length. Record the number (Machine Measured Length – ________inches) and compare it to the length you measured by hand. At this point you have to decide if the difference in the length measurements warrants recalibrating your machine. If you would like to recalibrate your machine continue reading this document.

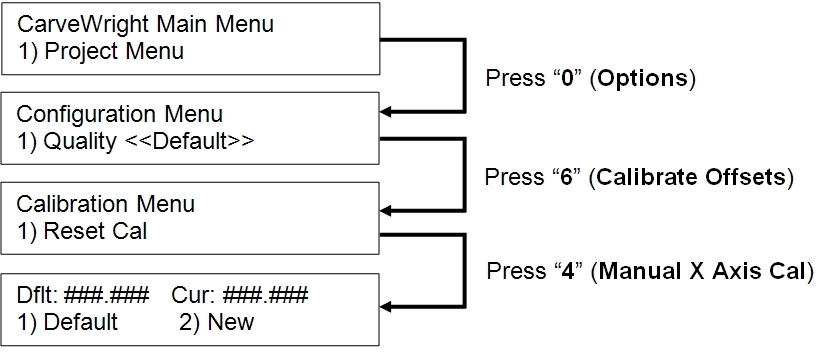

Before recalibrating, make sure that you have the latest CarveWright firmware version running on your flash card (version 1.161 or later). Next, navigate to the recalibration menu by following the directions and flow chart below.

- Turn on your machine and navigate to the Configurations Menu from the CarveWright Main Menu pressing the “0” (Options) key on the keypad.

- Navigate to the Calibrate Offsets menu item by using the up/down arrows and press ENTER, or select item 6 by pressing the “6” key.

- Navigate to the Manual X Axis Cal menu item by using the up/down arrows and press ENTER, or select item 4 by pressing the “4” key.

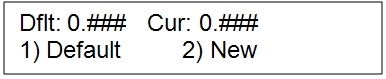

You are now at the screen that shows you the default calibration numbers (factory calibrated) as well as the current calibration setting for the length measurement. You now have two options:

- Pressing “1” (Default) will restore the current value to the factory default value.

- Pressing “2” (New) will allow you to type in a new value to adjust for the difference in measured lengths. New numbers can be entered with decimal or fractional values. Press ENTER to save once a value is entered.

To calculate the value to enter, first take a look at the difference in the measured lengths. If the hand measured length is longer than the machine measured length you will need to add units to the displayed current value, and conversely, if the hand measured length is shorter than the machine measured length you will need to subtract units from the current value setting.

To find the magnitude of the change to the current value subtract the two numbers (Length difference – _________inches). Although not an exact correlation, you should change the current value setting by 1 unit for every 0.03″ (or for every 1/32nd of an inch).

So now you have a direction (add or subtract) to change and a magnitude (number of units). As an example: say you have a board that measures exactly 36″ long by your tape measure and the machine measures board at 35.875″, adjust the X axis cal number by -4. If the current value was set to 890.000, change it to 894.000. Or if the machine measures 36.125″, adjust the X axis cal number +4.

Once the new value is entered you will see it appear as the Current value on the display. Go back and measure the board with the machine again and see how much closer the measured values become. Rerun the calibration routine as many times as necessary to attain the level of accuracy that you desire.

Calibrating the Y-Axis

You will want to consider calibrating the Y-axis if you are consistently getting an incorrect board width measurement or if you are seeing an offset in the centering of a project in the side-to-side direction. To do this calibration you will need a board at least 6″ wide that has clean and straight edges. Wider boards allow for better calibration accuracy.

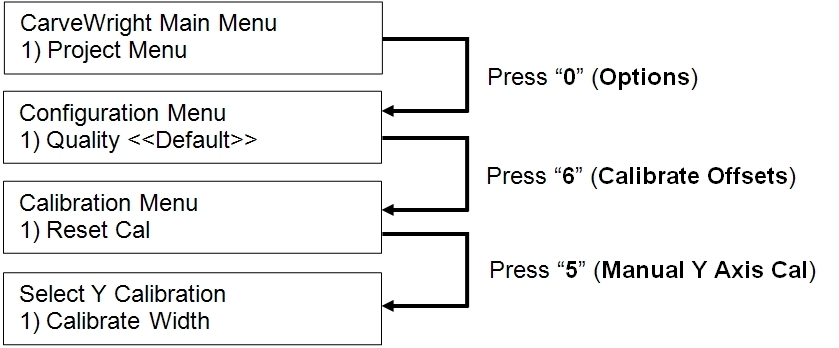

Before recalibrating, make sure that you have the latest CarveWright firmware version running on your flash card (version 1.161 or later). Next, navigate to the recalibration menu by following the directions and flow chart below.

There are two options in the Manual Y-Axis Calibration menu:

- Calibrate Width – This calibration will allow you to adjust the machine if it is measuring the width incorrectly.

- Calibrate Y Offset – This calibration will allow you to adjust the machine’s Y position if it is not placing a pattern in the right location in the side-to-side direction (i.e. not centering in the Y direction).

Calibrate Width Option

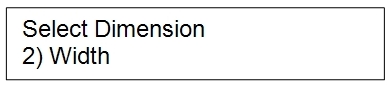

To begin the width calibration you will want to do a hand measurement and machine measurement of your board width. Measure and record your board width with as much accuracy as you can get in roughly the center of the length (Hand Measured Width – _______inches). Load the board into your machine making sure that it is centered under the Y-Truck, and measure it using the “Measure Board” function. This can be accessed by pressing the “7” (Measure) key on the keypad or by using the up/down arrows to navigate to the measure function from the CarveWright Main Menu. The display will then ask for the direction the user wishes to measure.

Press the “2” key on the keypad to measure the Width. Record the number (Machine Measured Width – ________inches) and compare it to the width you measured by hand. At this point you have to decide if the difference in the width measurements warrants recalibrating your machine.

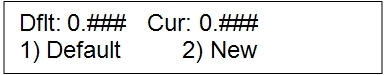

If you would like to recalibrate your machine continue reading this document. If you wish calibrate the width measurement select “1” from the Select Y Calibration menu shown above. You are now at the screen that shows you the default calibration numbers (factory calibrated) as well as the current calibration setting for the width measurement.

You now have two options:

- Pressing “1” (Default) will restore the current value to the factory default value.

- Pressing “2” (New) will allow you to type in a new value to adjust for the difference in measured widths. A screen will then appear that prompts you to input whether your hand measurement was Narrower (option 1) or Wider (option 2) than the machine measurement. (For example, if your board measures 6.1″ wide by hand but measures 6.05″ by the machine, you will select “2” to tell the machine that the actual measurement is wider.

The machine will then ask for the amount by which the measurement is off. Enter the new value in decimal or fractional form. In the example above type .05 and press ENTER to save the value. Repeat the board measure test and repeat the calibration steps as necessary.

Calibrate Y-Offset Option

If you are having issues with a pattern being carved off-center (even though it is centered in the software), select the Calibrate Y-Offset menu item.

The first step in this calibration is to carve a rectangular test region or shape centered on the board width. Run the project in the machine and tell it to center on width if it asks due to the board size. Measure the distance from each side of the board to the edge of the square. Obviously if the pattern is centered the offsets will be the same.

If they are not the same, record both the amount by which the two measurements differ (Difference = ______inches) and the direction in which the pattern needs to move in order to center it on the board. You will want to know whether the pattern needs to move Towards the keypad side of the machine or Away from the keypad side of the machine to achieve proper centering.

Once you select the Calibrate Y-Offset menu item you will see the screen that shows the default calibration numbers (factory calibrated) as well as the current calibration setting for the Y-Offset.

You now have two options:

- Pressing “1” (Default) will restore the current value to the factory default value.

- Pressing “2” (New) will allow you to type in a new value to adjust for the difference in measured offsets. A screen will then appear that prompts you to input whether the pattern needs to be moved Towards the Keypad (option 1) or Away from the keypad (option 2) for proper centering. For example, you carve a square and it is off-center by 0.1″ in the direction away from the keypad side of the machine. In this case you want to select option “1” to tell the machine that the pattern needs to move Towards the keypad side of the machine. The machine will then ask for the amount by which the measurement is off. Enter the new value in decimal or fractional form. In the example above, type .1 and press ENTER to save the value. Repeat the cut test and repeat the calibration steps as necessary.

DOWNLOADABLE PDF INSTRUCTIONS

CarveWright User Callibration